Rapid prototyping: What you need to know

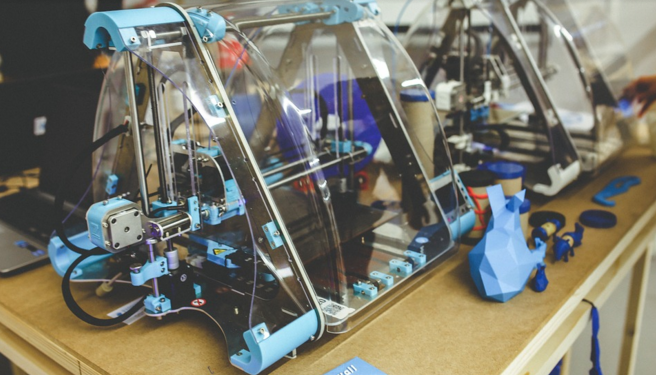

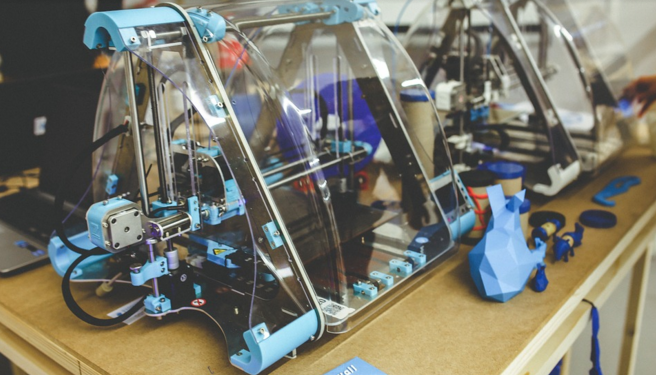

What is rapid prototyping? Most individuals will confuse rapid prototyping with 3D printing. Rapid prototyping also referred to as a rapid prototype, might also be a new term, especially if you aren’t in the manufacturing field. In the simplest form, the process involves creating prototypes that help to create an engineering product design.Â

This article will lay bare everything you would want to know about rapid prototyping. It will discuss its meaning, different methods of rapid prototyping, advantages, and more other information that will be beneficial to you. It would be best if you follow this article to the end to get enlightened. Let’s jump straight to its definition.

What Is Rapid Prototyping?Â

Rapid prototyping is a process that uses 3D Computer-Aided Design (CAD) to fast fabricate a model or an engineering product design. Conforming to Prototech Asia, the finalizing of the created part, model, or assembly is done through the addictive manufacturing method, commonly referred to as 3D printing. Furthermore, Prototech Asia is a company specializing in rapid prototyping services, and if the design created closely matches the end product, it’s referred to as a high-fidelity prototype. When there is a massive difference between the prototype and the final design, such is referred to as a low fidelity prototype.Â

How Rapid Prototyping Works

The whole process of rapid prototyping comprises a variety of manufacturing systems and technologies. Most of these processes also use layered additive manufacturing to come up with the required model or product.Â

Technologies used in rapid prototyping mainly include casting machines, high-speed machining, molding, and extruding devices. There are three processes involved in rapid prototyping processes. Here are the processes.

Â

- Additive manufacturing: This process is the most used in rapid prototyping. It involves adding substances to an already created physical substance to develop a unique, desirable shape. It is like the 3D printing method but a bit different in producing the desired models.Â

- Subtractive Manufacturing: With this process, the machine is fed with a block of material and then carves it to produce the wanted shape. The machine will mill, turn or grind the material until the desired shape is achieved.Â

- Comprehensive manufacturing: Here, a liquid or a semi-solid material is fed into a container to form the desired shape. After the shape is formed, the material gets solidified to produce a design or model. The method uses comprehensive sintering, molding, or casting methods to come up with a desirable product.Â

Prototyping Steps

The whole rapid prototyping process has three significant steps, as defined below.

- Step 1: Prototype stage: Here, designers replicate users’ descriptions or solutions into replicas. They take note of the user experiences and best practices for review.

- Step 2: The review stage: When prototypes are in place, companies will share them with individuals who contributed the ideas to see if they match their needs, descriptions, and expectations.

- Step 3: the refine stage: The designers will then collect feedback from the users and check on the reports to see the areas requiring changes and clarifications.

Â

When rejected, the whole process reverts to step one. After it gets approved, the prototypes get finalized and handed to the production unit to create the final product.

Is Rapid Prototyping the Same as 3D Printing?Â

As discussed above, most people do confuse rapid prototyping with 3D printing. These are two different methods, although much related. The rapid prototyping method is mainly confused with 3D printing because 3D was the first to make the prototypes before rapid prototyping. Each of the methods has made giant steps to now stand on their own.Â

Â

The main difference between 3D printing and rapid prototyping is that 3D printing is a manufacturing process to produce parts that make an end product. The rapid prototyping process results in an end product. In simpler terms, manufacturing experts use 3D printing and other methods to feed and create rapid prototyping. Rapid prototyping is the end product of 3D printing or a combination of 3D printing with other manufacturing processes.Â

Types of Rapid Prototyping

There are different types of rapid prototyping used to come up with an end product. These types include the below.

Â

- Selective Laser Sintering (SLS): This method is best used in plastic and metallic materials prototyping. It involves using a powder bed to build prototype layers, each at a time. The laser gets used in heating and sintering the powdered material to create a model. This process doesn’t produce a fine-end finished product. The surfaces of the finished product are always rough, while its strength isn’t as good as that of the parts made using the SLA process, explained below.

- Selective Laser Melting or Powder Bed fusion: Most people understand this process as powder fusion, and it’s primarily used in making substantial and complex parts. Manufacturers best use this method in susceptible industries, including automotive, medical, aerospace, and defense industries. In this process, the powder bed fusion uses metallic powder, which gets melted in layers to develop a prototype or produce parts using an electron beam or high-powered laser. Common materials used in this process include stainless steel, aluminum, titanium, and cobalt chrome alloys.

- Binder Jetting: This method allows the printing of different parts at the same time. However, these parts are not as strong as those produced by the selective laser sintering (SLS) method. In this method, a powder bed is used where nozzles spray liquids to bond the powder particles to create a layer of the desired part. The layers then get compacted with a roller before another layer is added. The process goes on and on. The finished part is then cured in an oven to fuse the powder and burn the binding agent to create a smooth finish of the product or model.

- Stereolithography (SLA) or Photopolymerization: This technique, fast and affordable, was first used in 3D printing before getting into rapid prototyping. It involves using a photosensitive liquid that gets solidified from one layer to another using computer-controlled UV rays.

- Fused Deposition Modeling (Material Jetting): This is a cheap, easy-to-use process, primarily found in non-industrial 3D printers. The process uses thermoplastic filaments melted in a printing nozzle before the liquid plastic is layered down according to the design on the computer. Before then, this process used to have poor resolution and produced weaker results. However, the process has continued to improve with technology, and it’s becoming faster and cheaper. Most companies are now incorporating it in product development.

- Laminated Object Manufacturing (LOM): Also known as sheet manufacturing, this method is cheaper and less sophisticated than SLS and SLM and does not require controlled conditions. Here, the process builds thin laminates, cut with laser beams to create a CAD pattern design. The previous layer gets bonded with the incoming layer until the part becomes complete.

- Applications: Here, product designers use applications to manufacturing prototype parts: the apps aid visualizations, designs, and development of the manufacturing process. Before then, designers used the method to create automotive industry parts but have now advanced to producing medical and aerospace parts. As part of the application, rapid tooling uses an injection or plug to facilitate the manufacturing process.Â

- Digital Light Processing (DLP): This process resembles the SLA but uses polymerization of resins which uses a more conventional light than the Stereolithography method. The method is also faster and cheaper and requires support structures and curing. You can also use Continuous Liquid Interface Production in this method, where the part gets pulled from the vat without using layers. When the part is pulled, it crosses a conventional light which alters its configuration to create the desired pattern.

Why Rapid Prototyping Is Important

The consumer market is changing at a fast rate. With the rising demand for varieties, companies need to develop new products faster to beat their competition. Rapid prototyping has become essential in developing these new products, which significantly satisfies clients’ needs. The process enables companies to realize the below objectives.

Â

- Faster Product development: With rapid prototyping, companies can develop and produce new products in record time to beat the competition. The process helps to speed up the development process, which could take days in normal circumstances.

- Final stage product verification: Companies can verify their products to ensure they reach their technical requirements and match the company objectives.

- Early-stage validation of design: Before then, companies used to wait until the product is complete to verify its design. Things have changed, and they can do this by getting samples through rapid prototyping before undergoing mass production.

- Testing: It allows the company to test its objectives with the products before coming up with the final design.

- Enables feedback: the whole process enables the end-user, clients, and participants to experience the product and give feedback. This process is done before mass production.Â

How Much Does Rapid Prototyping Cost?

There is no defined cost for the whole process. The final cost gets determined by several factors. These include:

Â

- The volume of the parts being created

- Materials used to create the parts

- The surface finish

- The post-manufacturing process required for the part

Â

This means that some parts of the same size can cost differently depending on the materials used and the post-manufacturing process required. It is essential to discuss the same with the developers before making an order. Â

Advantages of Rapid Prototyping

There are different advantages associated with rapid prototyping. Here is part of the list.

- It provides the ability to explore and realize concepts quickly: the whole process saves time and costs with its efficiency in exploring and realizing the concepts. It goes beyond product realization since it helps to get the properties and the design of the product.

- It communicates concepts concisely and effectively: The whole process takes in ideas and concepts from 2D visuals from different sources and turns them into physical products. It can take ideas from clients, collaborators, and colleagues and turn them into designs and products that will fit their needs.

- Applies repeated designs and makes changes that allow product evaluation and testing: The whole process provides a detailed roadmap of creating a product, incorporating changes that will make the product better. It develops and refines the product to fit the client’s needs.

- Saves time and money in setting up: You don’t need to have designated machines for different products. The company can use the same machines to produce prototypes for different products, reducing the time and cost of buying and maintaining several machines.

- It thoroughly tests and refines a concept: By minimizing design flaws and running small volume rapid prototypes, companies can eliminate costly design flaws that might not appear in early assessments. What the machine produces is a refined concept.Â

Disadvantages of Rapid Prototyping

- Insufficient Analysis: when focusing on a limited prototype, developers might get distracted in analyzing the whole project. They may not find a better solution and might stick with a lesser option in their engineering projects.

- Limited Options: The whole process can limit your designing options. Why is it so? While there are many options for making prototypes, you might overlook others, limiting yourself with rapid prototyping. There are functions such as creating interlocking parts which might produce better designs than rapid prototyping. When doing complicated projects, this limited choice of designing might not be the best.

- Creates user confusion: When the design reaches the final consumers, they might think it’s a finished product. When seen as a rough idea, they might not understand what the final product will look like. They might undertake or overlook the design, bringing confusion to the designers. The clients might also find a prototype feature that might not appear on the final product, confusing the whole idea.

In conclusion, you have learned a lot concerning rapid prototyping, as highlighted in this article. It’s now upon you to decide if you can incorporate it into your manufacturing business. Your selection will largely depend on the type of prototyping you need.Â

You can use prototyping to handle simple projects while having other options for sophisticated projects. Lastly, it would be best if you got a reputable supplier for your prototyping tools. You can do online surveys and check on reviews before making the final purchase.

You failed to mention rapid prototyping/3D printing of metal parts. There are a number of companies in that space – Markforged, Desktop Metal, Digital Alloys, etc. You get a finished, if a bit rough, solid metal part from their machines. Yes, more expensive than the desktop ones that make plastic parts, but important to include in your article for completeness.