The Human Side of Automation

From Michael Spencer and Diana Wolf Torres from AI Supremacy

If you are interested in the Semiconductor News cycle and AI chip news this is where I summarize the news.

Get Full Access to Semiconductor News

The Human Side of Automation:

Psychology in the Age of Collaborative Robots

| MICHAEL SPENCER AND DIANA WOLF TORRES JUL 8 |

To cap off a pretty eventful week in AI & emerging tech: if you know other robot enthusiasts you might want to share this with them.

When collaborative robots first arrived on factory floors, they represented more than a technological advancement—they sparked a profound psychological experiment. As these “cobots” moved from behind safety cages to work shoulder-to-shoulder with human operators, researchers began documenting a complex interplay of trust, anxiety, and adaptation that reveals as much about human nature as it does about our automated future.

“While robots have been increasingly integrated into manufacturing since their introduction in the early 1960s, true human-robot workplace collaboration is still in the early stages and is only recently being earnestly studied by academics,” explains Robert Gao, chairman of the mechanical and aerospace engineering department at Case Western Reserve University.

The Trust Foundation

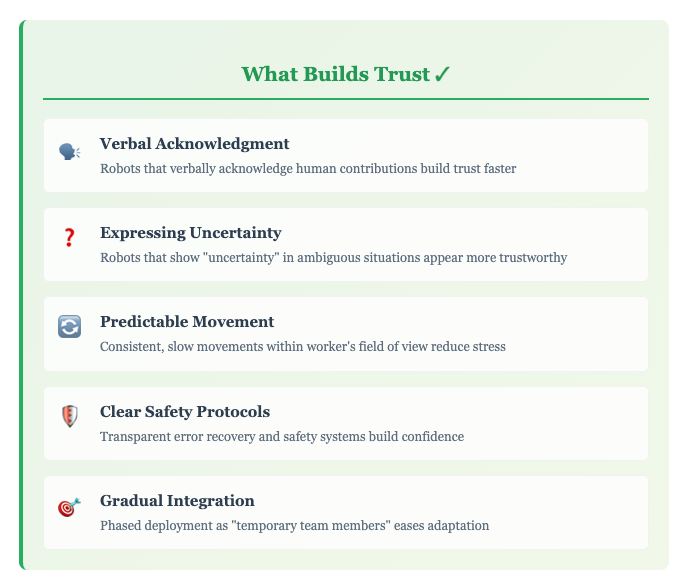

Trust forms the cornerstone of successful human-robot collaboration, but it operates very differently than trust between humans. Research from Case Western Reserve University shows that robots achieve 27% faster trust development when they verbally acknowledge human contributions and display “uncertainty” in ambiguous situations.

Workers develop what psychologists call “layered trust”—first evaluating basic competence (can the robot perform tasks safely?) and then building deeper confidence in adaptability. Unlike human relationships, robot trust lacks emotional reciprocity. Workers may trust a robot to perform tasks correctly, but don’t expect it to care about their well-being in the same way a human colleague might.

According to the research documented in the sources, 48% of workers report initial skepticism during the first two weeks of working with robots; however, this resistance follows predictable patterns across different workers and cultures.

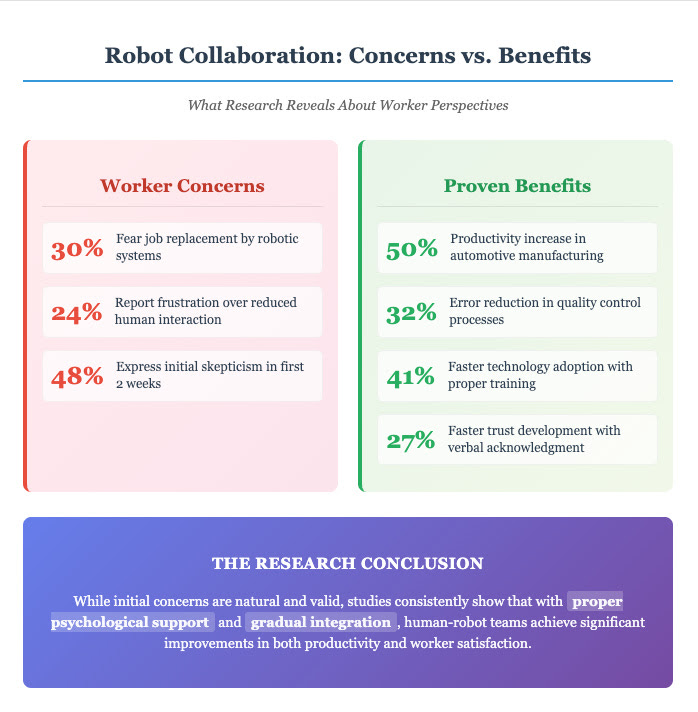

The Anatomy of Workplace Anxiety

Fear drives much of the initial resistance to robotic collaboration. According to the European Foundation study, 30% of workers fear job replacement, while 24% report frustration over reduced human interaction. But the sources of workplace anxiety around robots extend beyond simple job insecurity.

Physical proximity triggers stress responses even when workers rationally understand the safety features of cobots. Studies indicate that robotic end effectors approaching within a worker’s field of view at low speed cause significantly less mental stress than faster or unpredictable movements.

Interestingly, the “uncanny valley” effect—discomfort with human-like robots—plays a minimal roles in industrial settings. Industrial robots are deliberately designed to look mechanical, avoiding psychological confusion about their nature.

Articles this Week:

- AI reports in 2025 Say we are Underestimating Its Impact

- The AI Operating System for the Startup Founder

- Meta is Building an AI Superintelligence Team

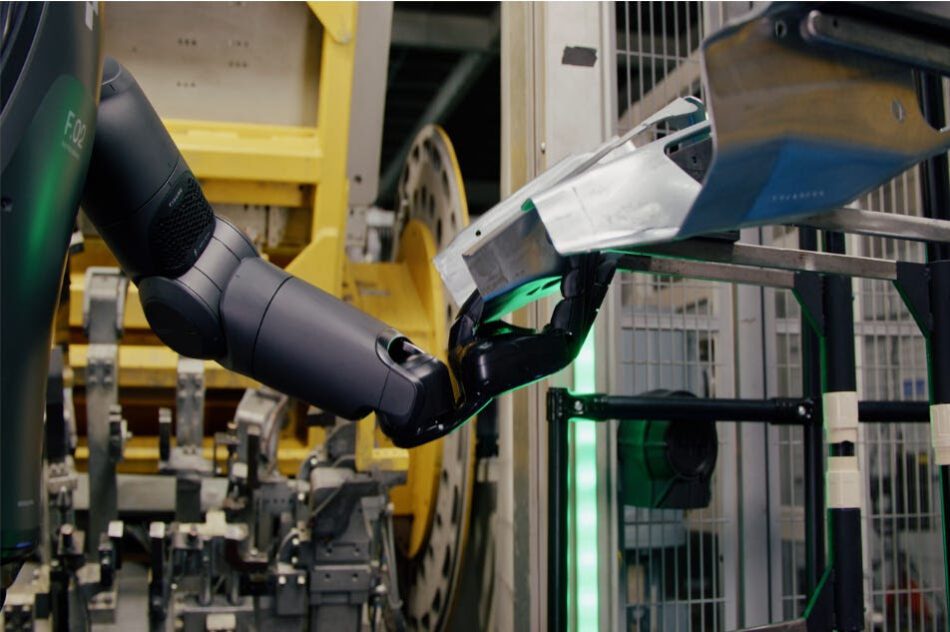

Image from BMW plant.

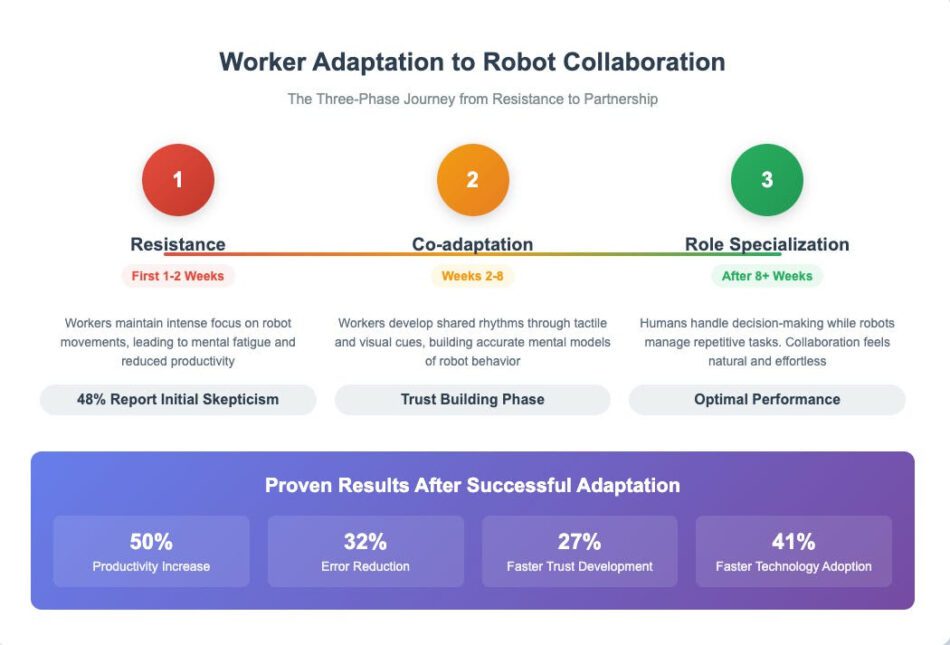

From Resistance to Partnership: The Adaptation Journey

Worker adaptation follows a consistent three-phase pattern documented across cultures and industries:

Phase 1: Resistance – Workers maintain intense focus on every robotic movement, leading to mental fatigue and reduced productivity. This hypervigilance typically lasts 1 to 2 weeks.

Phase 2: Co-adaptation – Workers begin developing shared rhythms through tactile and visual cues, understanding the robot’s patterns while building more accurate mental models of its behavior.

Phase 3: Role Specialization – Humans handle decision-making while robots manage repetitive tasks. Collaboration feels natural and cognitively effortless.

The timeline varies significantly based on individual factors—age, prior technology experience, and personality traits all influence the speed of adaptation.

The psychological principles translate into measurable workplace outcomes across multiple industries:

Automotive Manufacturing: Cobots handling welding while humans perform quality control achieved 50% productivity boosts and 32% error reduction, according to documented case studies.

Electronics: Dual training combining robot programming with conflict resolution led to 41% faster adoption and 18% lower turnover rates.

Healthcare: Parkinson’s assist robots with adaptive gait matching showed 22% improvement in patient mobility.

At BMW Group’s Spartanburg facility in South Carolina, four collaborative robots now equip the insides of BMW X3 model doors with sound and moisture insulation. “Previously, workers used a manual roller to adhere the insulation. This highly labor-intensive task is now performed by systems with roller heads on robot arms,” according to BMW’s documentation.

Harald Krüger, member of BMW AG’s Management Board responsible for production, explains the philosophy: “Robots that assist production workers by assuming labor-intensive tasks will characterize the factory of the future. Their benefits are strength and mechanical accuracy – and they perfectly complement humans’ flexibility, intelligence and sensitivity.”

The Psychology of Human-Robot Communication

“Most researchers anticipate humans taking on the more-nimble decision-making, while robots contribute by lifting heavy tools or putting the right tool at our side when needed,” notes Gao. “You could see this more on an assembly line, where the human is building an engine, screwing the spark plugs into the engine block and the robot is handing him the right tools and parts at the right time.”

This collaboration requires new forms of communication. Workers develop both verbal and non-verbal signals to coordinate with robotic colleagues, fundamentally changing workplace interaction patterns.

Cultural Variations in Robot Acceptance

Acceptance patterns vary significantly across cultures, with important implications for global manufacturers. According to documented research, Western and Chinese workplaces show 68% preference for robot autonomy, while Middle Eastern and Indian workplaces prefer 57% human-supervised autonomy.

Language customization proves crucial for acceptance: South African factories saw 39% higher engagement with native-language robot interfaces, while German manufacturers achieved 91% compliance using ISO-standardized visual cues.

Cognitive Load and Decision-Making

Working with robots fundamentally changes how humans process information and make decisions. Unlike working alone or with human colleagues, robot collaboration requires workers to maintain awareness of both human intuition and machine logic simultaneously.

The key is “cognitive offloading”—when robots handle routine decisions effectively, workers can focus mental energy on higher-level problem-solving and quality control. The level of automation determines how decision-making tasks can be allocated to robotic agents, potentially reducing overall cognitive load.

Building Psychological Safety

Successful human-robot collaboration requires more than technical integration—it demands psychological safety. Workers need confidence to stop robots when something seems wrong, experiment with new approaches, and report issues without blame.

Organizations achieving successful implementation invest heavily in predictable movement patterns that feel natural to human colleagues, clear communication about robot intentions and current states, and maintaining human control and decision-making authority.

The Future of Collaborative Manufacturing

The next frontier involves humanoid robots. Milan Nedeljković, Board Member for Production at BMW AG, recently stated: “With an early test operation, we are now determining possible applications for humanoid robots in production. We want to accompany this technology from development to industrialisation.”

BMW’s recent trials with Figure’s humanoid robots at their Spartanburg plant represent this evolution. “The Figure 02 is the most advanced humanoid robot in the world to reach the market so far,” according to Brett Adcock, founder and CEO of Figure. [video: Source BMW Group]

However, integration challenges remain significant. Ron Potter, Director of Robotics Technology for Factory Automation Systems, emphasizes that “many people don’t understand that collaborative robots are not a direct replacement for conventional robots.”

Implementation Best Practices

Based on documented research and real-world implementations, successful cobot integration requires:

Gradual Integration: Industrial psychologists emphasize phased deployment, introducing robots as “temporary team members” first to allow psychological adaptation.

Ergonomic Focus: The decision for introducing assembly robots was mainly based on ergonomic considerations, particularly for simple, highly repetitive work scopes that require considerable strength.

Worker Agency: Maintaining human control and decision-making authority helps preserve psychological comfort and job satisfaction.

Safety Systems: Advanced sensors and algorithms that detect human presence, swiftly halting operations to avoid accidents, are essential for building trust.

The Bottom Line

The psychology of human-robot collaboration reveals that success depends more on understanding human nature than perfecting robotic technology. When properly implemented with attention to psychological factors, human-robot teams can achieve significant improvements: 50% productivity boosts, 32% error reduction, and 41% faster technology adoption.

The most successful factories won’t just have the most advanced robots; they’ll have the deepest understanding of the human psychology behind collaboration. Research consistently shows that when human-robot teams find their psychological rhythm, both productivity and worker satisfaction increase.

As manufacturing continues evolving toward greater automation, the factories that thrive will be those that recognize the human mind as their most complex and valuable piece of equipment—one that requires as much attention and optimization as any robotic system.

Additional Resources:

Guarascio, D., Piccirillo, A., & Reljic, J. Robots vs. Workers: Evidence From a Meta-Analysis. Journal of Economic Surveys. https://doi.org/10.1111/joes.12699

BMW Group. “Humanoid Robots for BMW Group Plant Spartanburg.” BMW Group, 2024, www.bmwgroup.com/en/news/general/2024/humanoid-robots.html.

BMW Group. “Innovative Human-Robot Cooperation in BMW Group Production.” BMW Group Press, 17 Apr. 2019,www.press.bmwgroup.com/global/article/detail/T0209722EN/innovative-human-robot-cooperation-in-bmw-group-production?language=en.

BMW Group. “Successful Test of Humanoid Robots at BMW Group Plant Spartanburg.” BMW Group Press, 6 Aug. 2024,www.press.bmwgroup.com/global/article/detail/T0444265EN/successful-test-of-humanoid-robots-at-bmw-group-plant-spartanburg?language=en.

“Case Western Studies Human-Robot Relations.” Assembly Magazine, 17 Apr. 2019, www.assemblymag.com/articles/94860-case-western-studies-human-robot-relations.

“Cobots in Manufacturing: What You Need to Know.” PRIDE Industries, 4 Feb. 2025, www.prideindustries.com/our-stories/cobots-in-manufacturing.

European Foundation for the Improvement of Living and Working Conditions. “Human–Robot Interaction: What Changes in the Workplace?” Eurofound, 2024, www.eurofound.europa.eu/en/publications/2024/human-robot-interaction-what-changes-workplace.

“Optimizing the Human-Robot Workplace.” Case Western Reserve University – The Daily, 9 Apr. 2019, thedaily.case.edu/optimizing-the-human-robot-workplace/.

A guest post by Diana Wolf Torres