Precision and Purity: The Role of Industrial Ovens in Medical Device Manufacturing

Photo by Fábio Ranhola on Unsplash

In the tightly regulated world of medical device manufacturing, maintaining strict sterility and material integrity is critical. Industrial ovens serve as essential tools for achieving this, offering dependable solutions for heat sterilization, curing, and drying of medical components.

From polymer curing to the thermal treatment of surgical instruments, advanced oven systems ensure the precise environmental control needed to meet regulatory standards and performance expectations.

Heat Sterilization: A Proven Method in Healthcare Manufacturing

Dry heat sterilization is a well-established method for decontaminating medical equipment and device components that are sensitive to moisture or chemicals. By using controlled high temperatures—typically between 160°C and 180°C, this technique effectively eliminates microbes through oxidative damage.

According to ScienceDirect, dry heat sterilization is particularly valuable for materials like stainless steel, glass, and certain polymers where steam or gas sterilization may compromise structural integrity.

Supporting Curing and Material Stability

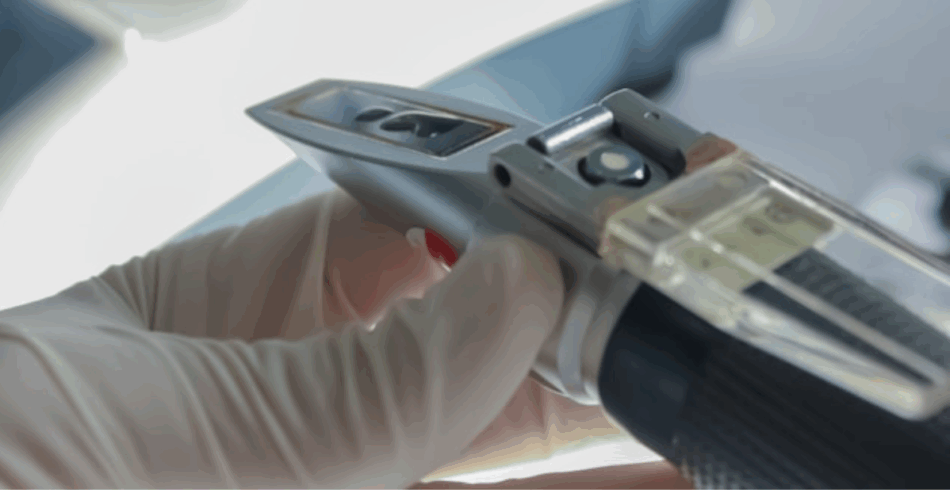

In addition to sterilization, thermal processing plays a vital role in material curing, especially for polymer-based or composite devices. Controlled heat application ensures that materials reach their final form, enhancing biocompatibility, durability, and mechanical strength. These processes are commonly used in manufacturing items like catheter tubing, implant coatings, and diagnostic housings.

Facilities looking for scalable solutions often rely on industrial oven systems built for high-throughput performance, designed to maintain uniform temperatures and support cleanroom compliance.

Lab-Based Applications in Device R&D

Laboratory ovens are also widely used during the research, development, and small-batch production of medical devices. These systems are critical for controlled drying, stability testing, and component pre-conditioning prior to sterilization.

Whether in prototyping or quality assurance, high-precision lab ovens offer the tight temperature control and repeatability needed to support reliable R&D operations.

Final Thoughts

Modern medical device manufacturing demands tools that offer precision, compliance, and consistency. From curing polymers to dry heat sterilization, industrial and laboratory ovens provide manufacturers with the control needed to meet strict healthcare standards. As devices become more complex and regulatory scrutiny grows, investing in dependable thermal processing solutions remains a cornerstone of quality and innovation.