Post Nike sneaker fiasco, a footwear design expert shares how and why basketball shoes can fail

By Emily Engle From Core77

Keep the below image in the back of your head for the next few minutes, as we’ll be dissecting how and why Duke basketball player Zion Williamson’s pair of Nike PG 2.5 basketball sneakers literally fell apart on court during a recent game:

Image via Business Insider

Ever since the incident went down, we’ve been wondering how, from a technical design standpoint, a pair of quality tested sneakers could have come apart this way during a game. To get the inside scoop, we consulted industrial designer Michael DiTullo, who has extensive experience working as a footwear designer at Nike (including in the Jordan division of the brand). Read his responses below and be sure to study DiTullo’s detailed basketball sneaker anatomy diagram at the end of this article:

Core77: Is shoe failure during a college/pro basketball game something new or has this happened before? If so, when and where has this happened before?

Michael DiTullo: Shoes do fail sometimes, though it is rare that one has a catastrophic failure. Eyelets can pull out, laces can break, tongues can be yanked too many times and separate. The stresses that elite athletes are putting on the product are immense. We are really designing F1 cars for them that a regular person can then go and buy. If you wear a modern basketball boot off the court you might find it stiff, or overly supportive, because they are designed for these very specific players who push themselves and the product to the extremes. I once designed a shoe for an athlete who insisted on taking the prototypes with him… he ended up wearing them in competition, and we were all stressed that something might happen because they were hand made design validation samples. Luckily they held up and he won in them, so they became his lucky pair.

The Converse React Gel incident was before my time, but it is well documented, including this quote from a Highsnobiety article on the subject:

“In addition to Hammell’s theory of stagnation, a bigger problem for REACT was perhaps linked to reports that the sneakers’ “bladders” were leaky, with juice seeping on to the court. Former Washington Bullet Tim Legler was on the NBA Today podcast in 2012 and shared a story about how his REACT sneakers had leaked during practice, causing Chris Webber to slip and almost injure himself. As Legler put it, “They’re out there, the ballboys are out on the floor wiping the practice court and it continued. Three or four guys slippin’, slidin’, and wipin’ out.”

What main questions would you ask yourself if you were in charge of handling this situation from a design perspective?

The first question I would ask myself is, “was this a production pair, or a pre-production/athlete production pair?” A lot of athletes have feet that are larger than the commercial production run, so special molds are cut, and those pairs are usually made up special. This also typically results in a product that is constructed much more carefully and rigorously for the high demands an elite athlete will put on the product. Since this is a special handmade run, I could see how an error in lasting or curing the adhesives, or in the strobel stitching of the upper could occur.

If it was a production run shoe, I’d ask if this is one time thing; can we replicate the failure in wear test labs or on courts with testers? If it does happen regularly, then I’d have to start picking apart the design. Is there enough wrap on the EVA to get good biding between the upper and the sole unit? Are the rubber outrigger and toe bumper sizable enough? Is it a textile or EVA strobel material, and is that robust enough?

“I like to think of [footwear design] as being in a mixing booth where I have all of these equalizers. I can turn them up and down, and getting the mix right is the difference between a flop and a track that everyone gets stuck in their heads for the summer. It is not going to happen by accident—you have to know what you are doing and have a vision for the end product.”

There is a lot more that goes into designing a piece of performance footwear than the aesthetic graphical break up. A lot of biomechanics, material properties, and construction techniques need to be considered. There are best practices for all of these things that vary from company to company, but as designers we often want to push those boundaries while we are on our quest to make the product stronger, lighter, faster, more flexible, more comfortable, more supportive, grippier. Some of these goals are diametrically opposed, so understanding how to strike the right balance is critical.

What are some of the technical reasons why the shoe could have come apart?

Without seeing the shoe in person I can only speculate. I would assume there is an entire team of people looking into this issue. None of the major brands take this lightly. I know from my time at Nike there is a complete player focus and obsession. Looking at the way the foot came out of the shoe, I would look into the midsole bonding and strength of the stobel material. I’d love to see these shoes and really dissect the problem.

When I first started working in Jordan, I was amazed to see a pair of MJ’s sneakers after a game. Stitches would be blown out, rubber would be peeling—the shoes would be creased and distorted after just a couple of hours of play. These products are being pushed to the edge. The lighter, more comfortable and more flexible you make the shoe, the less durable it is. The more supportive and durable you make it, the less comfortable it is. As a designer you are really trying to fine tune the attributes to the specific player. Typically athlete products are given extra QA to make sure something like this doesn’t happen.

What are some common misconceptions about the footwear design process, especially when it comes to designing sneakers for professional athletes?

In my experience, most other designers have no idea how complex performance footwear design is. As a footwear designer you have to understand traditional soft good construction techniques as well as modern welding and knit constructions. You have to know about the difference between injection molding, compression molding, and cut and buff EVA production techniques for midsoles and when to use which. You need to know the difference between cold cement compression molding, capsules and vulcanization for outsole and when to use which ones of those. You need to learn about biomechanics of different activities that can be very different like repetitive linear motions of running versus the dynamic pivots, jumps, and sprints of basketball and then balance all of that with what is going on in fashion, so that hopefully this performance product will be adopted by the masses.

I like to think of being in a mixing booth where I have all of these equalizers. I can turn them up and down, and getting the mix right is the difference between a flop and a track that everyone gets stuck in their heads for the summer. It is not going to happen by accident—you have to know what you are doing and have a vision for the end product.

*****

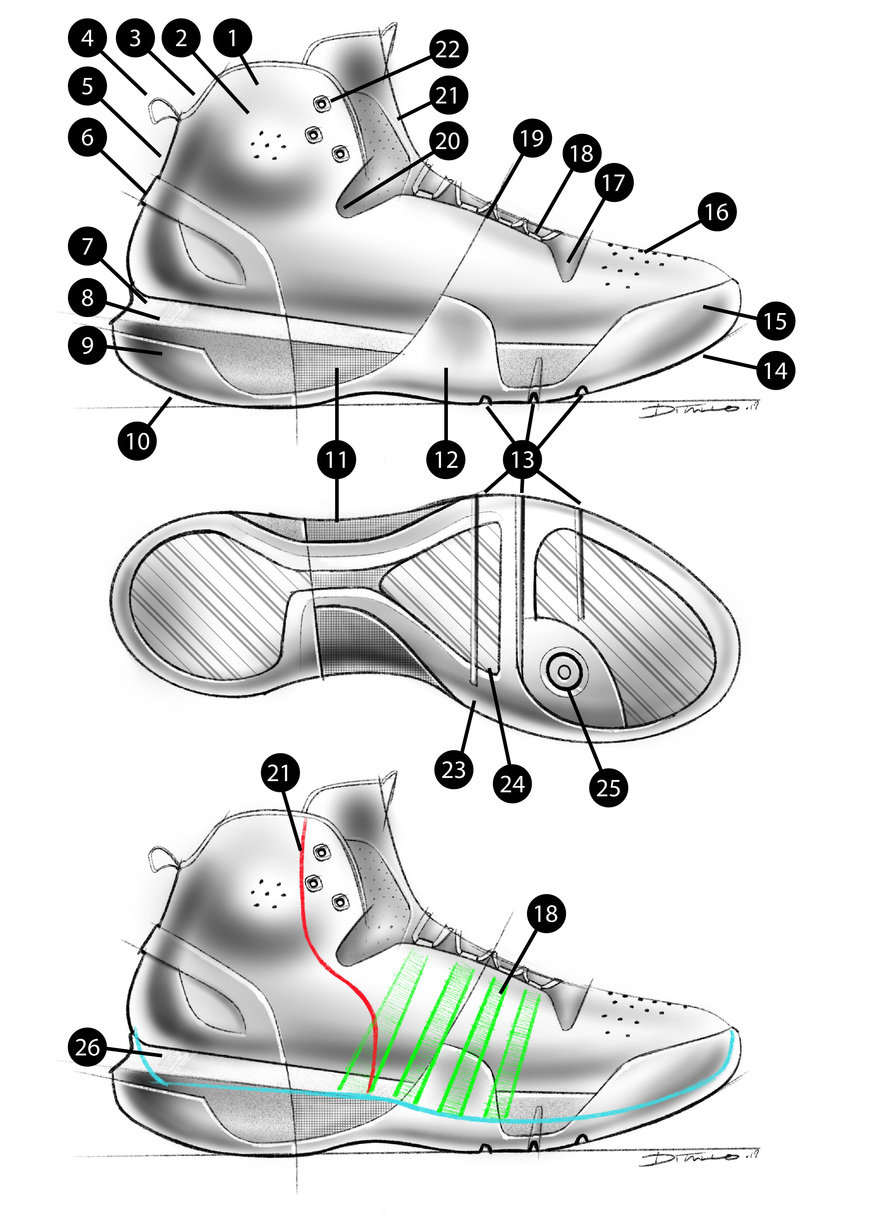

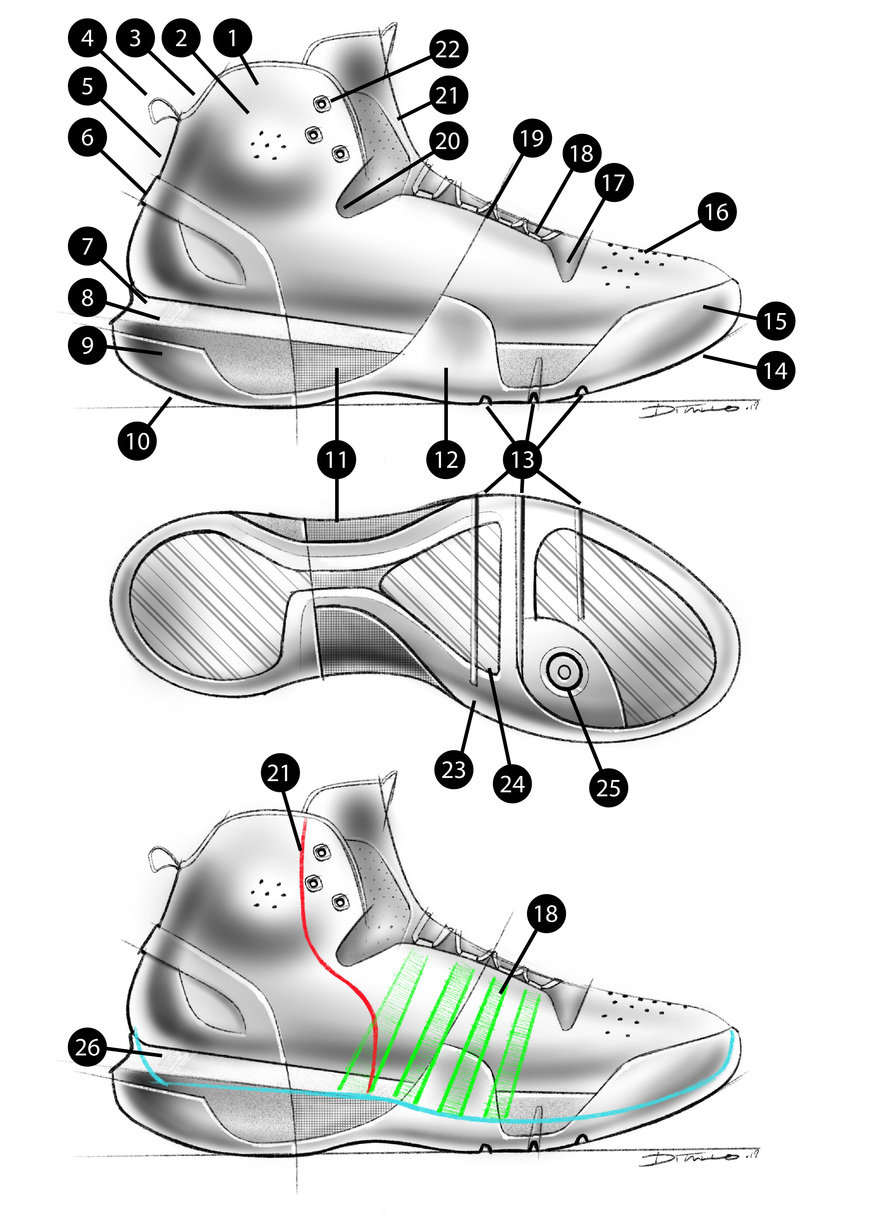

Below is a diagram of the anatomy of a basketball sneaker that DiTullo was kind enough to sketch up for us. You can refer to his detailed key below the image—we recommend printing this out as a resource:

Original diagram by Michael DiTullo

1) Upper: generally the soft parts of the shoe. It can be sewn, welded, knit, or any combination of the three. It can have a traditional tongue, a taco tongue, a bootie construction or a partial bootie. It can be single, double, or hybrid lasted to the tooling. I could talk for a week just about the upper.

2) Malleolus Padding: a little extra padding for this sensitive ankle joint is customary. On the Jordan XX1 and XX1PE it was actually a heat activated molded toe box material.

3) Achilles Notch: this little notch elevates pressure on the Achilles tendon.

4) Pull Tab: seems simple, but having one is nice.

5) Heel Rake: a little heel rake helps keep the heel locked down on the footbed. Too much and it hurts!

6) Heel Counter: these can either be an internal heat activated material or in this case and external injection molded part. It gives 3D shape and structure to the heel of the upper making a nice cup to keep the heel located.

7) Tooling: generally all the molded parts of the shoe. Generally a combination of injection and compressions parts put into an assembly often called the sole unit. Don’t forget tooling has to be opened for each part in each size and it doesn’t scale uniformly.

8) Midsole: generally injection molded EVA (typically a proprietary compound) in a performance product. It can also be compression molded or in the case of vintage runners it is made of laminated cut and buffed sheets of EVA.

8) Heel Wrap: a little extra bonding surface here helps prevent delaminations. A lot of little things like this add up to a great product.

9) Heel Kick: the surface of the outsole rolls up so that a player coming down in a foot strike rolls pressure onto the mid foot through the gate onto the ball of the foot (metatarsal heads).

10) Outsole: generally compression molded, sometimes in different densities or carbon compositions. In vintage product this would be a capsule that is stitched to the upper and in even older product it would be uncured rubber that would be vulcanized directly to the upper. Both of those older techniques are great for durability and rigidity but they are also stiff and heavy compared to modern product.

11) Shank: this can either be an internal top loaded plastic, carbon fiber, or kevlar (sometimes called a credit card shank) or in this case it is an external part laminated between the EVA midsole and rubber outsole. The benefit of being external is you can have it wrap up the sidewall which makes it extra rigid. This part helps carry energy from the heel strike through the gate to the balls of the feet. It also helps keep the shoe from torquing making a stable platform to land on.

12) Outrigger: this is a part of the outsole that wraps up sometimes past the midsole. The rubber is much stiffer than the EVA so having this part can help keep the foot onto of the midsole in dynamic cutting and pivots on court. These can be really important.

13) Tooling Flex Notches: They don’t look like much, but elevating a little material here under the metatarsal heads of the foot increases flexibility a lot.

14) Toe Spring: this is the amount that the toe bends upward. A greater amount of toe spring helps with rolling through the gate when running.

15) Toe Bumper or Toe Wrap: If an outsole is going to delaminate it usually does it in the toe or heel. Having this bumper adds a lot of bonding margin that is going to improve durability. In sports like basketball and tennis where there is a lot of toe drag with some players it is going to make a big difference.

16) Vamp Perfs: These perforations in a leather vamp are going to improve ventilation and also flexibility. The little things add up. Of course on a knit shoe to textile vamp you don’t need this.

17) Eyerow Flex Notch: There the eyerow meets the base of the tongue you will often see a bit of a jog. This simple detail give the soft 2 dimentional materials of the upper a place to flex.

18) Gillies: These strips of webbing, sometimes called gillies, capture the laces and should go all the way down to the strobel at the base of the foot so as you lace up you are literally pulling the shoe to the foot from the footbed upward.

19) Seams: A seam can stretch 2-5mm per game. If you have 10 seams on a shoe, that is a lot stretch! A good practice is to minimize them, but the fewer seams you have the less efficient the patterns are in terms of nesting parts to be cut out of the roll of material. The simpler uppers are generally reserved for the more expensive signature shoes. Typically the seams will be done in such a way that allow the shoe to be “color-blocked” uniquely, meaning that by changing colors and materials it can look almost like a different model.

20) Flex notch: another one. This one allows the ankle to flex a bit and helps with fitting the shoe. Feet can be very different one to the next.

21) Tongue: obviously, but the same of it matters a lot. For a basketball shoe you generally want it to be wider to wrap the foot a bit. This is because players often have their ankles taped up which means they need a wider overall throat opening. In this case the young is a semi bootie construction meaning it wraps all the way to the strobel in the mid foot making half of a sock.

22) Eyelets: typically reinforced either internally or externally. Players will crank down on their laces so hard and the stretch the shoe so much in play that if this is not reinforces the lade could tear out.

23) Variable Radius: on a basketball shoe, the medial side (inside) radius of the outsole will often be much larger than the lateral side (inside). This very subtle detail allows for easier transitions with medial side push offs and more stability when cutting.

24) Traction: different types of activities requite different kinds of traction patterns. With the multidirectional nature of basketball and the smooth surface of the court, the 50% up vs down and angles of herringbone are most common.

25) Pivot Point: most basketball outsoles have a smoother area with less traction under the first metatarsal head (base of the big toe) that helps the foot pivot more smoothly on the court.

26) Footbed: the actual height off the ground the foot interface is. In a basketball shoe it will typically be sunk into the tooling quite a bit so there is amble bonding margin to prevent blow outs and delimitation. Each company has it’s standard heights and offsets that carry by activity based on testing their cushioning compounds and platforms.

For more on this story go to: https://www.core77.com/posts/84725/Post-Nike-Sneaker-Fiasco-a-Footwear-Design-Expert-Shares-How-and-Why-Basketball-Shoes-Can-Fail?utm_source=feedburner&utm_medium=feed&utm_campaign=Feed%3A+core77%2Fblog+%28Core77.com%29